Manual transmissions are known for durability but require regular maintenance to prevent breakdowns. Learning repair basics can help diagnose issues early, ensuring smooth gear operation and longevity.

Overview of Manual Transmission Components

A manual transmission consists of gears, bearings, and synchronizers that work together to enable smooth shifting. The gear set includes various ratios for speed control, while bearings support moving parts. Synchronizers ensure seamless gear engagement, and the clutch facilitates power transfer between the engine and transmission. Proper lubrication is essential for longevity.

Importance of Regular Maintenance

Regular maintenance for manual transmissions prevents wear and tear, ensuring optimal performance. Fluid changes and inspections help identify issues before they escalate. Neglecting maintenance can lead to costly repairs, such as replacing damaged gears or bearings. Consistent care extends the lifespan of the transmission and enhances driving efficiency.

Common Signs of Transmission Problems

Common signs of manual transmission issues include unusual noises, difficulty shifting gears, and fluid leaks. Grinding sounds or hesitation between gears can indicate worn components like synchronizers or bearings. Addressing these symptoms promptly prevents minor issues from becoming major repairs.

Identifying Symptoms of a Faulty Manual Transmission

A faulty manual transmission often causes grinding noises, difficulty shifting gears, and slipping between gears. Recognizing these symptoms early helps prevent further damage and ensures vehicle reliability.

Grinding or Noisy Gears

Grinding or noisy gears are common signs of worn synchronizers or damaged gear teeth. These noises occur during shifting and indicate improper meshing of gears. Addressing this issue promptly prevents further damage to transmission components and ensures smooth operation. Regular lubrication and inspections can help mitigate such problems.

Difficulty Shifting Gears

Difficulty shifting gears can result from worn clutch facings, low transmission fluid levels, or damaged synchronizers. This issue may also stem from misaligned gear components or faulty linkages. Addressing these problems early prevents further damage and ensures smooth, efficient gear transitions. Regular maintenance is key to avoiding such complications.

Slipping or Hesitation Between Gears

Slipping or hesitation between gears often indicates worn clutch packs, faulty solenoids, or low transmission fluid pressure. This can lead to inconsistent power delivery and potential engine stalling. Identifying the cause early is crucial to prevent further damage and maintain smooth gear transitions. Regular fluid checks and component inspections are essential.

Leaking Transmission Fluid

Transmission fluid leaks often stem from damaged seals, gaskets, or pan bolts. Early detection is crucial, as low fluid levels can cause overheating and gear damage. Inspecting the transmission pan and lines regularly helps prevent costly repairs and ensures optimal performance. Addressing leaks promptly is essential.

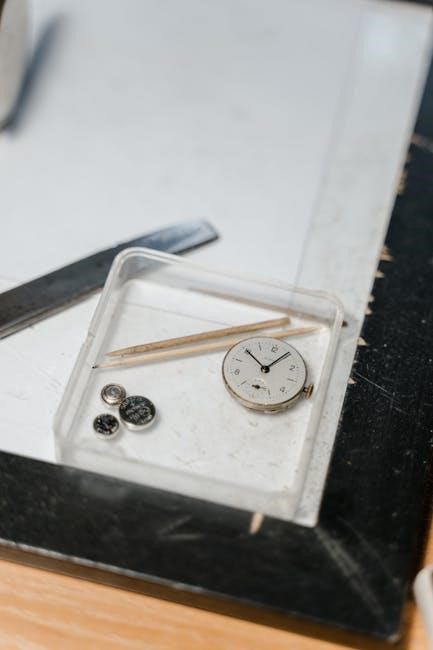

Tools and Equipment Needed for Repair

Essential tools include wrenches, screwdrivers, and gear pullers. Specialized equipment like transmission jacks and bearing presses may be required for complex repairs. Proper tools ensure efficiency and safety.

Essential Tools for Transmission Repair

Basic tools like wrenches, sockets, and screwdrivers are vital. Specialized tools such as gear pullers and bearing presses are often necessary for dismantling and reassembling components. A transmission jack ensures safe handling, while seal installers prevent damage during reassembly, making the repair process smoother and more efficient overall.

Specialized Equipment for Advanced Repairs

Advanced transmission repairs often require precision tools like hydraulic presses and bearing splitters. These tools help in safely removing and installing bearings and gears. A transmission dyno can test rebuilt units for functionality before installation, ensuring reliability and performance; Proper equipment is crucial for professional-level repairs.

When performing manual transmission repair, wear protective gear like gloves, safety glasses, and a face mask. Ensure the vehicle is securely lifted and supported to prevent accidents. Proper ventilation and adherence to safety protocols are essential to protect against injuries and exposure to harmful substances. Manual transmission repair involves systematic steps, starting with disassembly, inspection, and replacement of faulty components. Proper reassembly and fluid replacement ensure functionality. Replacing a clutch involves removing the transmission, inspecting components, and installing a new clutch kit. Ensure proper alignment and bleeding of the hydraulic system for smooth engagement. Always follow manufacturer guidelines to avoid damage. Rebuilding a manual transmission involves disassembling, inspecting, and replacing worn-out parts like bearings, seals, and gears. Clean and reassemble components with new gaskets and lubricants. Proper torque specifications and alignment are crucial for optimal performance and longevity. Always refer to the repair manual for specific instructions. Replacing a damaged gear set requires precise alignment and lubrication to ensure smooth operation. Inspect and clean the transmission case thoroughly before installation. Use specialized tools to press bearings and align gears correctly. Always follow manufacturer guidelines for torque and installation specifications. Proper installation prevents future mechanical failures. Common manual transmission issues include worn synchronizers, bearing failure, and damaged gear teeth. Each problem requires specific diagnostic and repair techniques to restore proper transmission function and prevent further damage. Worn-out synchronizers cause gear grinding and difficulty shifting, especially into first or second gear. Replacing them requires disassembling the transmission, inspecting components, and installing new parts. Proper lubrication and alignment during reassembly ensure smooth operation and prevent future wear. Regular maintenance can help identify and address this issue early.

Bearing failure in a manual transmission often results in loud noises, vibration, and resistance during gear shifts. Replacing faulty bearings requires precise alignment and specialized tools. Early detection through noise monitoring can prevent further damage to connected components, ensuring a cost-effective repair and maintaining transmission performance. Damage to gear teeth can cause grinding noises, difficulty shifting gears, and complete transmission failure. Regular inspection and lubrication are crucial to prevent wear. Replacing damaged gears ensures smooth operation and avoids costly overhauls, extending the lifespan of the manual transmission system effectively. Manual transmission repair costs vary based on parts replacement, labor fees, and transmission condition. Factors include gearbox type, mechanic expertise, and location, impacting overall expenses significantly. Parts replacement costs for manual transmissions depend on component type and quality. Clutches, gears, bearings, and synchronizers vary in price due to brand and durability. OEM parts are typically more expensive, while aftermarket options offer cost savings without compromising performance and reliability in most cases. Labor costs for manual transmission repairs vary based on the complexity of the job and the mechanic’s expertise. Replacing a clutch or rebuilding a transmission can take several hours to multiple days, with labor rates typically ranging between $75 to $200 per hour, depending on location and shop rates. Deciding between repairing and replacing a manual transmission involves evaluating the extent of damage and costs. Repairs are cost-effective for minor issues like worn-out synchronizers, while replacement is often necessary for severe damage, offering a long-term solution but at a higher initial expense. Regular fluid changes, inspecting the clutch cable, and monitoring gear lubrication are key to preventing manual transmission issues. These practices ensure smooth operation and extend the lifespan of the transmission components.

Regular fluid changes are crucial for maintaining the health of a manual transmission. Clean fluid ensures gears and bearings are properly lubricated, reducing friction and wear. It’s recommended to replace the fluid every 30,000 to 60,000 miles to prevent degradation and contamination. This simple maintenance can prevent costly repairs. The clutch cable plays a vital role in smooth gear transitions. Regular inspection helps identify frays or wear. Replacing a damaged cable ensures consistent clutch engagement, preventing slippage or difficult shifting. Always use a high-quality replacement to maintain optimal performance and driver control. Proper gear lubrication is essential for reducing friction and wear. Regularly check transmission fluid levels and condition. Clean or replace the fluid filter as needed to ensure gears remain well-lubricated, preventing overheating and premature wear. This helps maintain smooth operation and extends the transmission’s lifespan. Identifying transmission issues early prevents costly repairs. Use diagnostic tools to analyze symptoms, perform visual inspections, and listen for unusual noises. This approach helps pinpoint problems accurately, ensuring timely fixes and optimal performance of your manual transmission system. Diagnostic tools are essential for identifying manual transmission issues. Scan tools can read error codes, while pressure gauges and leakage testers help detect fluid-related problems. These tools provide precise insights, enabling effective troubleshooting and ensuring accurate repairs, which are critical for maintaining transmission health and performance over time. Visual inspections are crucial for assessing manual transmission health. Look for fluid leaks, worn components, and signs of damage. Check the clutch, gears, and bearings for excessive wear. Regular visual checks can help identify potential issues early, preventing costly repairs and ensuring optimal performance. Abnormal noises during gear shifts can indicate issues such as worn synchronizers or damaged bearings. Grinding, clunking, or whining sounds often signal problems. Identifying these noises early helps diagnose issues before they escalate, ensuring timely repairs and maintaining transmission efficiency. Regular listening can prevent major breakdowns. Common mistakes in manual transmission repair include incorrect gear installation and improper alignment of components. These errors can lead to further damage if not addressed promptly, emphasizing the need for careful attention to detail during repairs.

Incorrect gear installation is a common repair mistake that can lead to grinding gears, difficulty shifting, and premature wear on transmission components. Proper alignment and seating of gears ensure smooth operation and prevent costly damage. Always refer to the manufacturer’s specifications for correct installation techniques to avoid such issues.

Improper alignment of transmission components can lead to uneven wear, noise, and complete system failure. Misaligned gears, bearings, or shafts disrupt the smooth operation of the transmission, causing vibrations and performance issues. Precise alignment is crucial for maintaining optimal functionality and extending the lifespan of the transmission. Neglecting proper lubrication can cause excessive wear on gears and bearings, leading to premature failure. Transmission fluid is essential for reducing friction and preventing overheating. Insufficient or incorrect lubrication can result in costly repairs and compromised performance, emphasizing the importance of regular fluid checks and maintenance. Regular replacement of transmission fluid is crucial for maintaining smooth gear operation and preventing overheating. Contaminated fluid can lead to serious damage, requiring costly repairs. Always consult a mechanic if unsure about the process or fluid type. Checking transmission fluid levels ensures optimal performance. Locate the dipstick, wipe it clean, and insert it again to get an accurate reading. The fluid should be between the minimum and maximum marks. If low, top it up with the recommended type to maintain viscosity and prevent damage. Always refer to the vehicle’s manual for specific instructions. Draining old transmission fluid is crucial for maintaining performance. Locate the drain plug, position a pan underneath, and allow the fluid to flow out completely. Once empty, refill with the manufacturer-recommended fluid type. Use a funnel to prevent spills and ensure the fluid level is within the specified range. Always refer to the vehicle’s manual for guidance. Selecting the correct transmission fluid is essential for optimal performance. Refer to the vehicle’s manual to identify the recommended fluid type. Common options include mineral-based, synthetic, and specialized formulas for high-performance or older transmissions. Using the wrong fluid can lead to premature wear and system failure. Always verify compatibility. A transmission replacement is necessary when repair costs exceed replacement value or damage is extensive. Severe internal damage, persistent failures, or outdated parts often necessitate a full replacement for long-term reliability and performance. A thorough inspection of the manual transmission involves evaluating gear wear, bearing condition, and internal components. Visual inspection, performance testing, and fluid analysis reveal the severity of damage. If extensive wear or multiple component failures are found, replacement may be more cost-effective than repair. Repairing a manual transmission is often more cost-effective for minor issues like replacing bearings or seals. However, extensive damage may make replacement more economical. Labor costs, part availability, and transmission age are key factors in deciding the most financially viable option. If your manual transmission experiences severe damage, such as cracked gears, extensive bearing failure, or internal corrosion, replacement is often the only solution. Persistent leaks, inability to engage gears, or significant slippage are clear indicators that a new transmission is required. Always wear protective gear, including gloves and safety glasses. Ensure the vehicle is securely supported by jack stands. Work in a well-ventilated area to avoid inhaling harmful fumes. Always use sturdy jack stands and ensure the vehicle is on a level surface. Raise the car slowly and refer to the owner’s manual for correct lifting points. Double-check the stability of the stands and never work under an unsupported vehicle for safety. When handling sharp or heavy parts, wear thick gloves and safety goggles to prevent injuries. Use a lifting strap or trolley for heavy components like gear sets or transmission casings. Ensure a firm grip and avoid sudden movements to maintain control and safety during repairs. Always perform repairs in a well-ventilated space to prevent inhaling harmful fumes from transmission fluid and cleaning agents. Open windows or use fans to circulate air, ensuring a safe working environment and reducing health risks associated with chemical exposure during manual transmission repair.Personal Protective Gear and Safety Precautions

Step-by-Step Repair Process

Clutch Replacement Procedure

Rebuilding the Transmission

Replacing the Gear Set

Common Issues and Solutions

Worn-Out Synchronizers

Bearing Failure

Damage to the Gear Teeth

Cost Factors in Manual Transmission Repair

Parts Replacement Costs

Labor Costs and Time Estimates

Comparing Repair vs. Replacement

Maintenance Tips to Prevent Future Issues

Regular Fluid Changes

Inspecting and Replacing the Clutch Cable

Monitoring Gear Lubrication

Diagnosing Transmission Problems

Using Diagnostic Tools

Visual Inspection Techniques

Listening for Abnormal Noises

Troubleshooting Common Repair Mistakes

Incorrect Gear Installation

Improper Alignment of Components

Overlooking Lubrication Requirements

Transmission Fluid Replacement

How to Check Transmission Fluid Levels

Draining and Refilling Fluid

Choosing the Right Type of Fluid

When to Replace the Entire Transmission

Assessing the Extent of Damage

Comparing Repair Costs to Replacement Costs

Signs That Replacement is Necessary

Safety Tips for DIY Transmission Repair

Proper Jacking and Support Techniques

Handling Sharp or Heavy Components

Working in a Well-Ventilated Area